Quicktron X Yishion

Yishion, a prominent Chinese fast fashion brand with a global footprint of over 6,000 stores, faced shifting market demands characterized by frequent small-batch orders and the necessity for urgent order prioritization. To adapt to this evolving landscape, the company recognized the need to transition from a rigid "production line" approach to a more flexible "production processes" model. This shift aimed to overcome challenges such as resource allocation inefficiencies, prolonged lead times, and need to accommodate varying worker skill sets.

Challenges And Objectives

Evolving Market Demands: Frequent small-batch orders and the need for rapid order prioritization required a flexible production approach.

Resource Allocation: Inefficient resource allocation was impacting productivity and operational efficiency. 3. Lead Time Reduction: Prolonged lead times needed to be minimized to meet customer expectations.

Lead Time Reduction: Prolonged lead times needed to be minimized to meet customer expectations.

Adaptability: They needed a scalable and flexible solution that can match the needs of seamless production.

The primary objectives were to:

Implement a flexible production process that could efficiently handle small-batch orders.

Optimize resource allocation to enhance productivity and operational efficiency.

Significantly reduce lead times to meet customer expectations..

Adapt to varying worker skill sets for seamless production.

Solution and Benefits

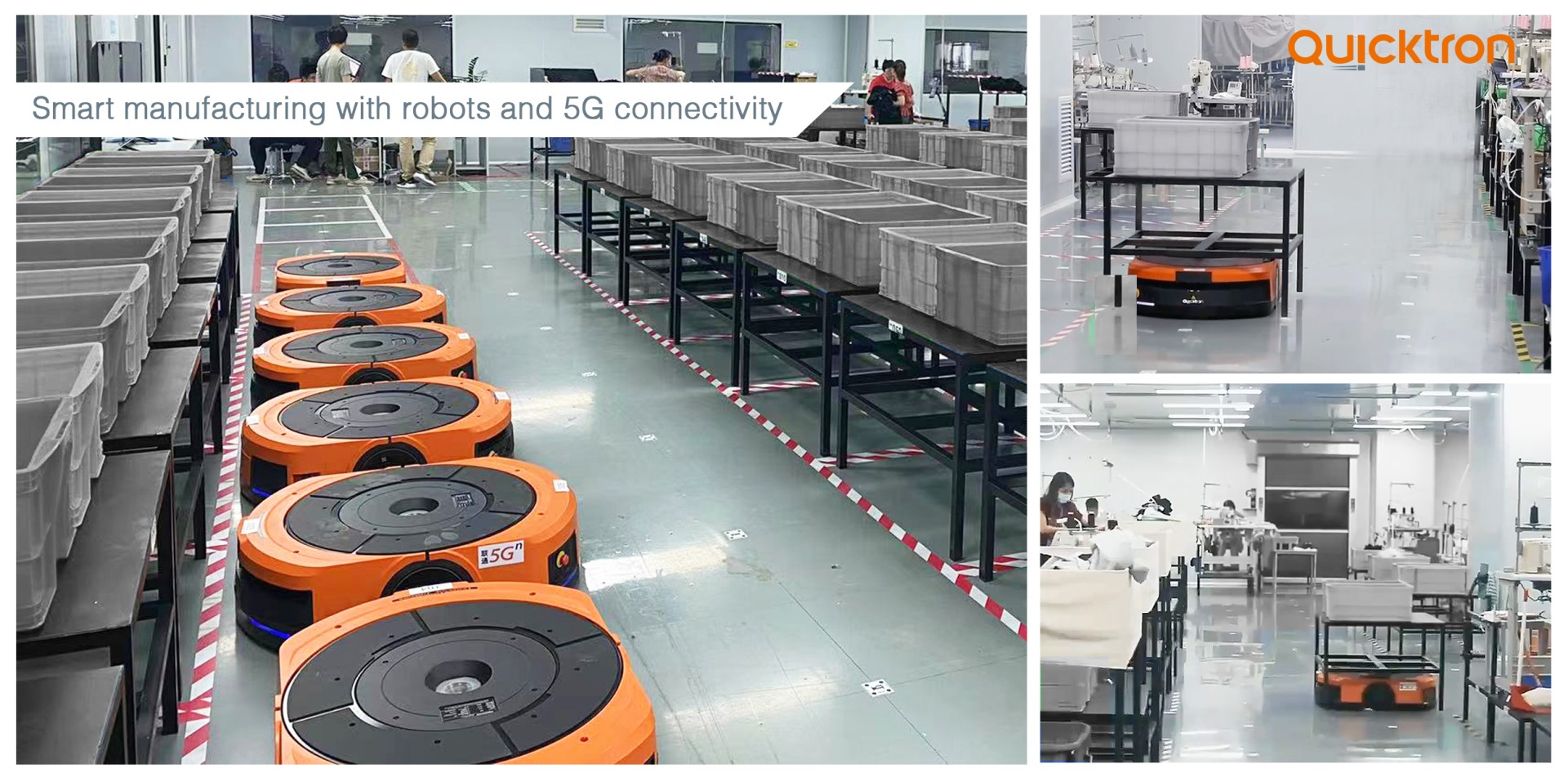

Quicktron introduced a transformative solution by implementing a 5G-enabled smart moving system. This innovative approach assigned tasks to robots and workers based on their strengths, aided by robots that delivered materials from one point to another via 5G-connected points. This integration optimized production processes, significantly enhancing efficiency and output in the face of complex operational challenges.

Efficiency Surge: Output efficiency per worker increased by an impressive 34%.

Resource Optimization: Resource allocation was streamlined, enhancing overall productivity and operational efficiency.

Reduced Lead Times: Prolonged lead times were significantly reduced, aligning Yishion with customer expectations.

Adaptive Workforce: The system seamlessly adapted to varying worker skill sets, ensuring smooth production.

Sustainability: The implementation led to a remarkable 90% reduction in energy consumption, aligning with sustainability goals.

"Quicktron's 5G-enabled smart moving system has been instrumental in optimizing our production processes, increasing efficiency, and reducing energy consumption. These advancements position Yishion for continued success in the fast-paced world of fast fashion."

Yishion

Related Cases