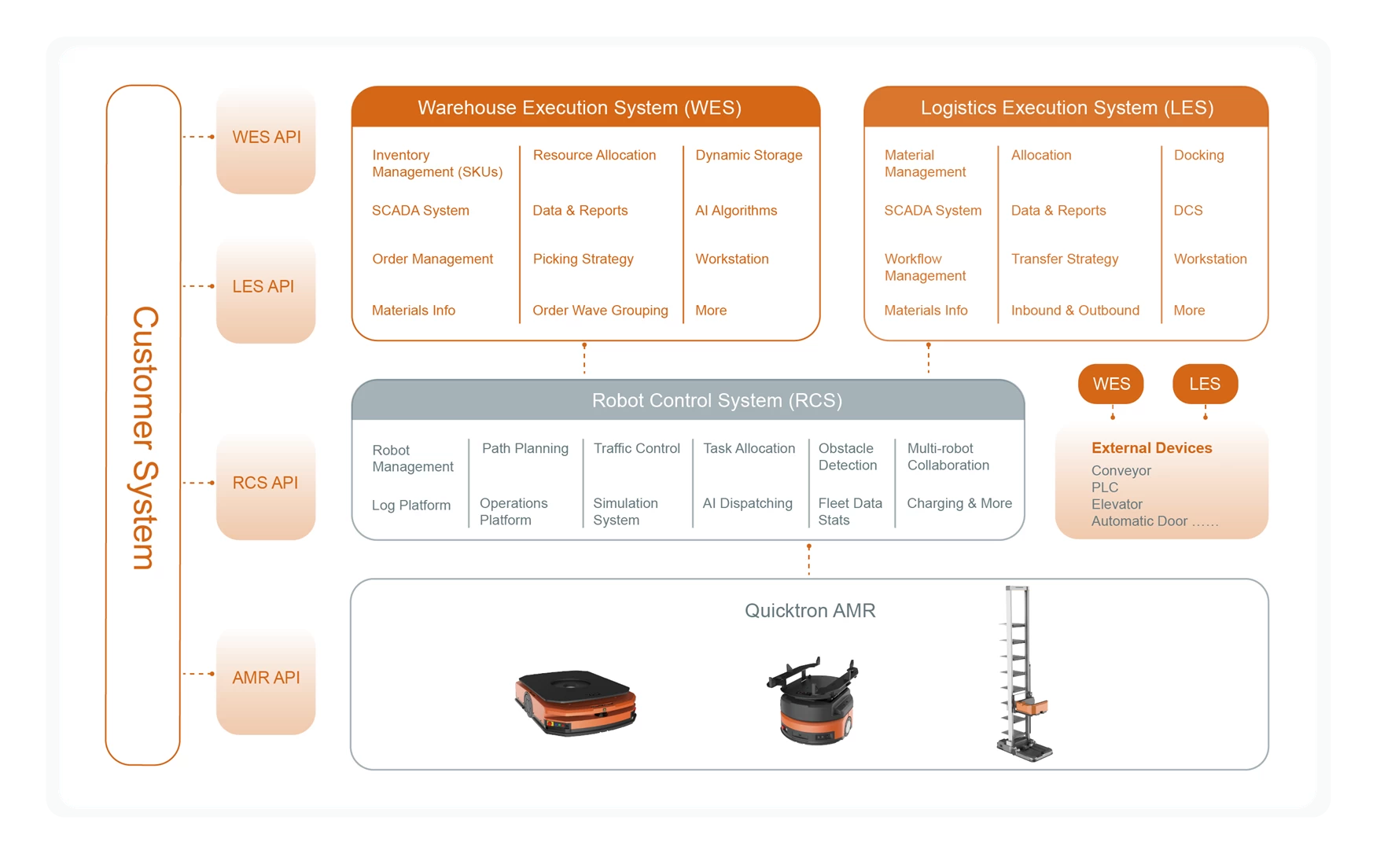

Software Platform

Warehouse Execution System WES

The Warehouse Execution System (WES) is the core of Goods-to-Person picking scenarios, orchestrating essential functions like inventory control, SKU management, order processing, and workstation coordination. By optimizing storage placements and leveraging AI algorithms, the WES ensures efficient order wave grouping, reducing travel times and enhancing overall picking efficiency. High-demand goods are stored at accessible lower levels and upfront, further enhancing storage efficiency. This intelligent system acts as a central hub, harmonizing warehouse operations, and maximizing resource utilization in the dynamic landscape of modern logistics.

Robotic Control System RCS

Quicktron's Robotic Control System (RCS) stands as a pinnacle of efficiency, expertly managing and synchronizing robotic elements to achieve meticulous control. Responsible for task scheduling, robot dispatching, operation, and maintenance oversight, RCS harnesses diverse scheduling algorithms to allocate tasks optimally, enable multi-robot path planning, manage traffic, charge, ensure safety through emergency stops, and more. This versatility empowers RCS to seamlessly coordinate various robot types in different scenarios, unlocking maximal efficiency through collaborative efforts.

Logistics Execution System LES

Quicktron's Logistics Execution System (LES) used in Smart moving scenarios functions as the operational backbone of supply chain logistics, seamlessly connecting high-level systems to on-ground operations. It manages material allocation, docking, workflows, and transfer strategies using AI algorithms. LES optimizes tasks like order processing, material handling, and inbound and outbound logistics, ensuring accurate real-time data integration. By orchestrating material flow and workflows, LES enhances efficiency, reduces lead times, and improves overall supply chain performance.

How Does our Software Algorithms Work?

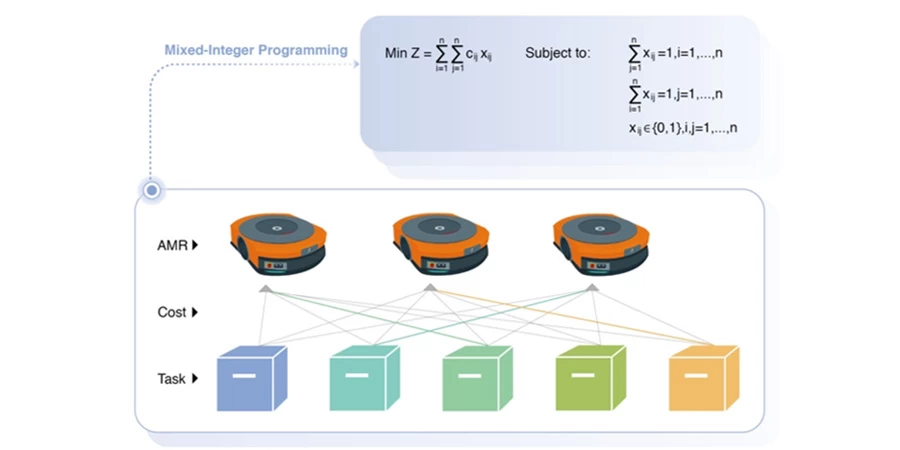

Multi-robot coordination

With the combination of heuristic and exact integer algorithms, Quicktron executes seamless coordination among hundreds of robots performing tasks simultaneously. Additionally, in QuickBin application scenarios, two different types of robots efficiently work together and in smart moving applications, Quicktron robots also effectively coordinate with other equipment.

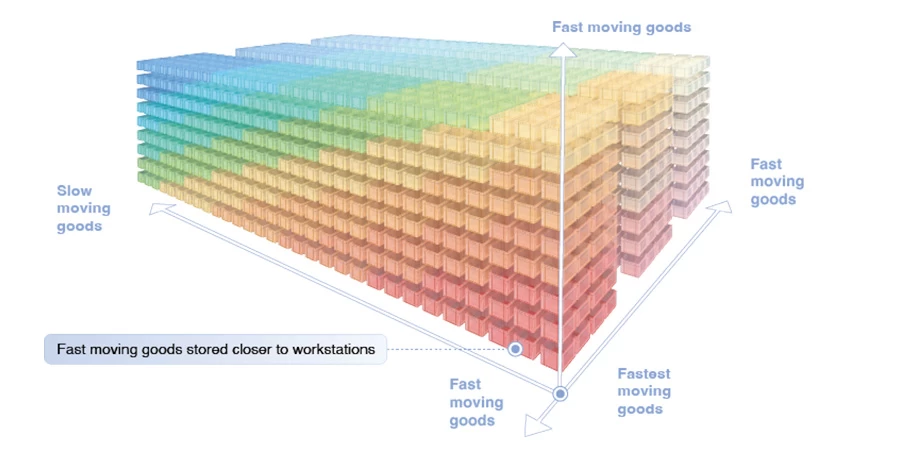

Dynamic storage

The system predicts the future demand by analyzing order history to determine the optimal location for shelves and bins. Optimized storage shortens the distance to workstation, enhancing picking efficiency.

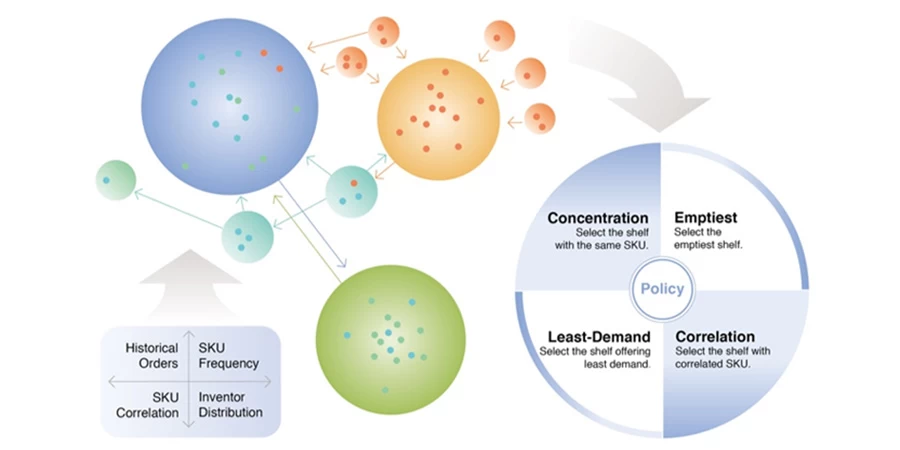

Storage assignment

Diversified inventory

Analysis of product size, SKU frequency, and other order parameters allows the better storage space management and inventory diversification.

Centralized storage of related goods

The system analyzes outgoing orders to group related goods, enhancing shelf hit rate.

Order waves grouping

Based on order and SKU correlation analysis, the system generates optimal order waves for picking one order at a time or multiple orders simultaneously.

Task allocation

Dynamic task allocation reduces robot detours and idle time, enhancing overall productivity.Robots follow one another in 1-2 seconds interval saving the operator’s waiting time.

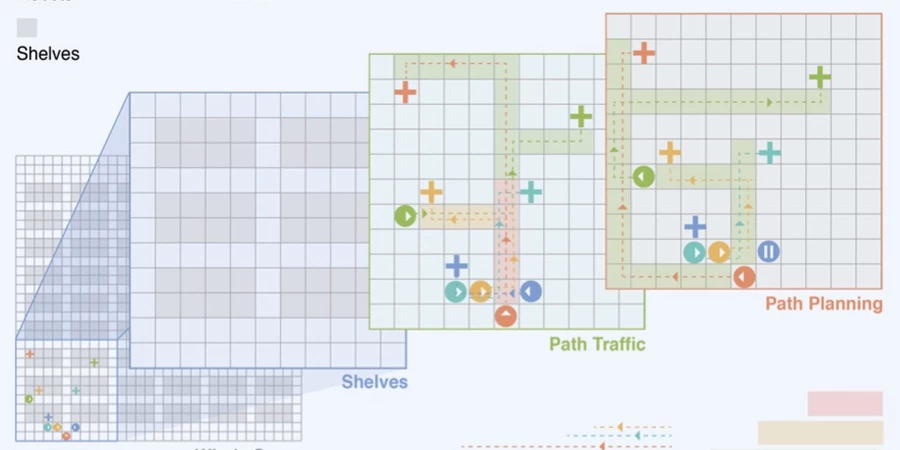

Path planning

To maximize the traffic efficiency and ensuring seamless high-speed operations, the shortest optimal path is planned for each robot, which immediately switches to re-planning mode in case of any irregularity.