Quicktron X TCL

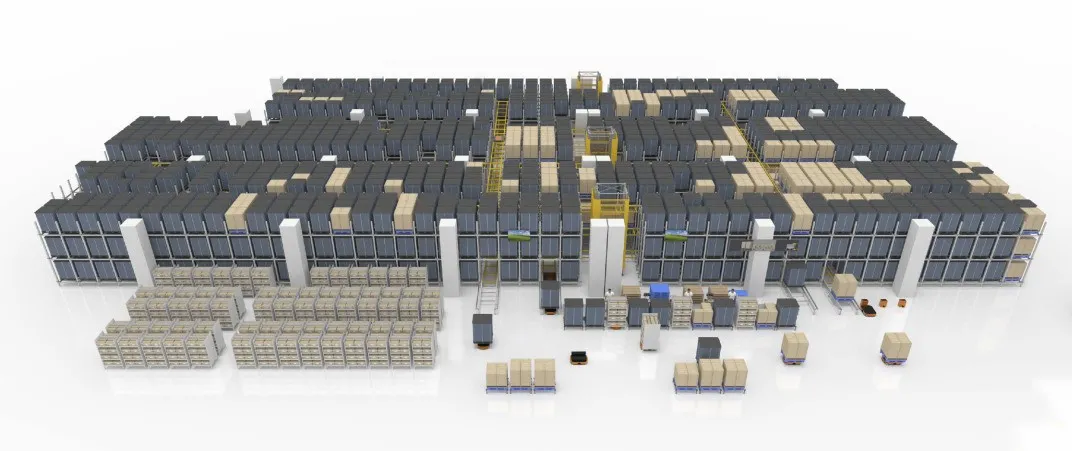

In response to the increasingly stringent demands for warehouse management within the electronics manufacturing industry, Quicktron Intelligent Technology has partnered with Guangdong Wankezi Intelligent Control Technology Co., Ltd., a subsidiary of TCL, to jointly develop a leading intelligent warehousing solution. This innovative project has achieved are revolutionary breakthrough in efficiency within an irregularly shaped warehouse spanning approximately 3100m², utilizing a pioneering 'Four-Way Shuttle + AGV' hybrid system.

The Automation Breakthrough in Electronics Warehousing

Guangdong Wankezi Intelligent Control Technology Co., Ltd., a core component manufacturing enterprise under TCL Air Conditioner, boasts an annual production capacity of 18.5 million inverter controllers. With the rapid growth in business volume, traditional warehousing models faced three core pain points:

1. Deployment Challenges in Complex Warehouse Environments

• Architectural Constraints: The warehouse had numerous beam obstructions, making the deployment of automated equipment challenging.

• Complex Operations: Multi-floor collaborative operations and mixed human-robot presence led to significant safety hazards.

2. Insufficient Operational Flexibility

• Inter-warehouse Collaboration Difficulties: Slow response times in cross-warehouseresource allocation and low management efficiency.

• Weak Anti-Fluctuation Capability: Significant seasonal demand changes made it difficult for the existing inventory turnover system to cope.

3. Stringent Accuracy Management Requirements

• High-Standard SKU Management: Electronic products strictly adhered to a 100% first in, first-out (FIFO) principle.

• Precise Inventory Control: The accuracy requirement for ledger-to-physical inventory reconciliation was ≥99.99%, with a single error or omission potentially resulting in losses of tens of thousands of yuan

Quicktron Robot Deployment Overview

Proposal

| Category | Details |

| Quicktron Automation Area | M150B |

| Four-Way Shuttle Vehicles | 39 units |

| Latent AGVS | 1500 kg |

| Lifts | 249 units |

| Pallet Position | 333 units |

Solution and Benefits

From Simulation to Reality: Redefining Warehouse Efficiency During the initial planning phase of the project, the Quicktron team conducted in-depth on site investigations of the client's conditions, precisely calculated equipment requirements, and designed a cross-zone storage solution for irregular architectural layouts based on the client's actual scenarios. Due to the influence of beams between columns, a three-story (three-dimensional warehouse area) with varying layouts was designed within the warehouse, where the clear height of the beams was 4.9m.

Through simulation animations, the team intuitively demonstrated the operational effectsafter the project's launch, ensuring the client's clear understanding and feasibility of thesolution. In the AGV equipment calculation, the team combined the inbound and outbound flow rates to configure 10 latent AGVs, with an additional 2 units for multi-layer shelf operations, and 3 sets of online charging piles. Simultaneously, for the four-way shuttle system, based on the inbound, outbound, and return flow demands, 10 four-way shuttle vehicles (including 1 dedicated cross-floor transfer vehicle) were designed. The lifts were flexibly adjusted to 3 sets according to architectural constraints, ensuring efficient access to the three-story warehouse area (totaling 2690 pallet positions).

Project Results

1. Inbound Accuracy Rate: 100%, completely solving the problem of mis deliveries and omissions.

2.Inbound and Outbound Efficiency: Increased by 70%

3. Space Utilization: Increased by 300%.

4. Labor Cost: Reduced by 60%.

Project Highlights

• Precise Calculation: Based on traffic data to match equipment quantities, accommodating both regular and irregular scenarios.

• Flexible and Agile: Dynamically optimizes lift and cargo space layout in response to architectural constraints (e.g., beam height); flexibly expands solutions based on customer business development.

• Visualized Implementation: Seamless transition from simulation to reality, verifying the reliability of the plan.

• Human-Machine Collaboration: Automated closed-loop design for abnormal handling and manual intervention, reducing human error.

Meet QuickMix: Quicktron’s All-Scenario Intralogistics Solution in the real world, storage isn't one-size-fits-all. Some operations involve multiple container types: shelves, totes, and pallets, all coexisting within a single facility.To address these hybrid scenarios, Quicktron offers QuickMix: a powerful solution designed to seamlessly integrate multiple systems and modules. QuickMix enables flexible combinations of: Tote-to-Person,Shelf-to-Person,Pallet-to-Person, QuickBin, QuickBin Ultra, QuickCube. It’s a modular solution built on standardized technologies, designed to handle diverse container types and easily adapt to the varying throughput demands of our customers.QuickMix is built to grow with your business.Flexible. Scalable. Scenario-ready.

The Quicktron team, with their professional capabilities, turned the impossible into possible.This project has become an intelligent benchmark for us to showcase extenally.

TCL GROUP

Related Cases