AMRs: Catalysts for Resilient Supply Chains in Flu Seasons

Introduction:

In the intricate world of logistics and supply chain management, unforeseen challenges have the potential to disrupt the seamless flow of goods and services. The impact of flu outbreaks and health crises on these critical systems has gained heightened attention in recent times. Influenza, a persistent public health problem, affects approximately a billion people globally each year, with a significant economic burden on organizations. The US alone faces an estimated US$16.3 billion annually, in projected lost earnings due to the flu, contributing to the total economic burden of $87.1 billion from annual influenza epidemics. The flu can also have a significant impact on organizations and workplaces through increased employee absenteeism and reduced productivity. In this article, we will explore the multifaceted problems faced by logistics and supply chains during health emergencies, with a specific focus on the role of Autonomous Mobile Robots (AMRs) in mitigating these challenges.

The Ripple Effect of Flu Outbreaks on Logistics:

While the immediate impact of a flu outbreak or health crisis is felt in public health, its repercussions extend far beyond hospitals and healthcare facilities, affecting diverse industries, including logistics and supply chains. The COVID-19 pandemic laid bare vulnerabilities in the global supply chain, emphasizing the need for greater resilience in the face of future disruptions.

Challenges Faced by Logistics and Supply Chains:

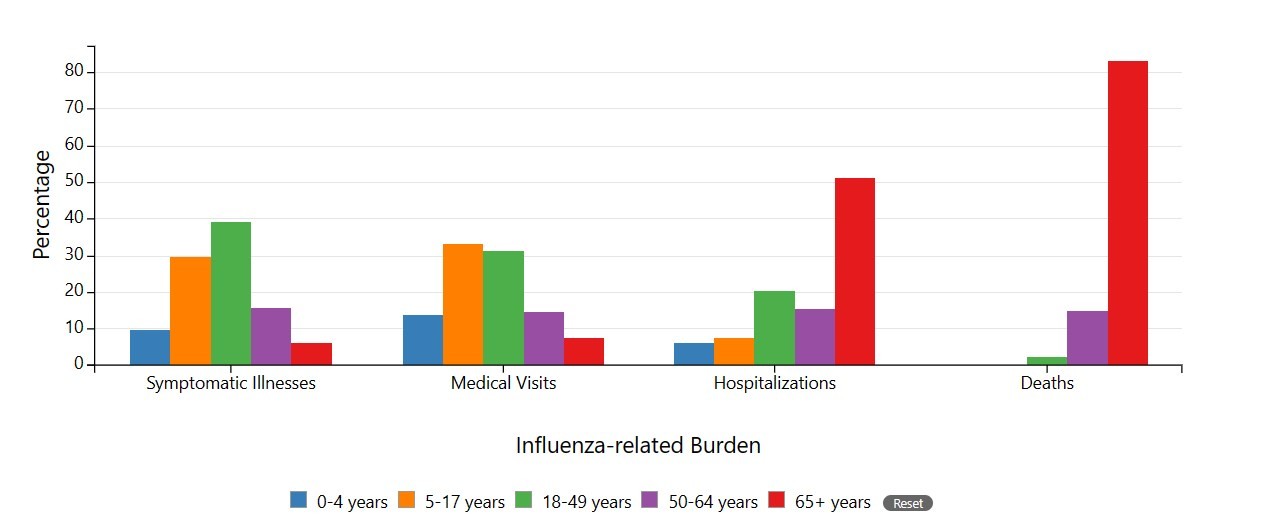

1. Workforce Disruptions: Flu outbreaks result in a significant reduction in available manpower due to illness or quarantine measures. This shortage disrupts the daily operations of warehouses, distribution centers, and transportation networks. The severity of the 2023 influenza season, marked by higher hospitalization rates and longer illness durations, exacerbated the impact on worker shortages. Center for Disease Control and Prevention (CDC) estimates that, from October 1, 2023, through November 25, 2023, there have been 1.8- 3.6 million flu sicknesses in the USA. Employees with COVID-19 or flu were less likely to go to work than people with other ARIs. Amid the pandemic, 66.7% of employees with COVID-19 and 48.3% with other ARIs didn't go to work.

2. Increased Demand for Essential Goods: During health crises, there is often a surge in demand for essential goods such as medical supplies, pharmaceuticals, and hygiene products. This sudden increase in demand places additional strain on supply chains that may already be grappling with reduced workforce capacity. Online retailers often experience a surge in orders during outbreaks, causing delays in deliveries and stressing fulfillment capabilities. (Source: National Retail Federation) Investing in resilient supply chains can help mitigate the impact of disruptions on the availability of essential goods.

3. Supply Chain Disruptions: Global supply chains heavily depend on international trade and transportation networks. Disruptions caused by health crises, including travel restrictions, demand fluctuations and inventory management issues lead to delays in production and distribution. Such disruptions can significantly impact businesses, affecting revenue, logistics, and reputation. According to a survey conducted by Hubs, 57% of businesses state that disruptions in the supply chain significantly affect their company’s revenue.

The Role of AMRs in Mitigating Logistics Challenges:

Autonomous Mobile Robots (AMRs) have emerged as a transformative technology in the realm of logistics and supply chain management. These intelligent machines are designed to operate autonomously, carrying out tasks without direct human intervention. Here's how AMRs can play a crucial role in overcoming the challenges posed by flu outbreaks and other health emergencies:

1. Contactless Operations: AMRs can perform various tasks, including material handling and transportation, without direct human contact. This feature becomes particularly valuable during health crises, where minimizing human interaction is essential to prevent the spread of diseases. Due to these benefits, there has been a noticeable increase in the adoption of robotics in recent years. According to Grand View Research, The global warehouse robotics market is expected to reach USD 17.29 billion by 2030, growing at a compound annual growth rate (CAGR) of 19.6% from 2023 to 2030.

2. Reducing Dependence on Human Labor: In situations where the workforce is significantly impacted, AMRs can step in to handle routine and labor-intensive tasks. This ensures a continuous and reliable flow of operations despite a reduced human workforce. Automation can replace redundant manual supply chain activities, drive productivity gains, and protect against margin squeeze and cost increases. A 2022 survey by MHI found that 82% of logistics and supply chain professionals believe that AMRs will significantly impact their labor requirements in the next five years. Dwight Klappich, Vice President and Fellow in Gartner’s Supply Chain Practice expressed that “by 2027, over 75% of companies will have adopted some form of cyber-physical automation within their warehouse operations, labor shortages and challenges retaining talent, coupled with technology advances such as machine learning and AI, will continue to drive adoption of smart robots.”

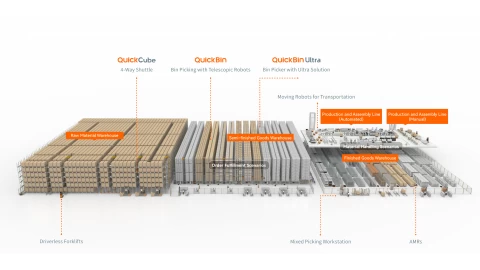

3. Flexibility and Adaptability: AMRs such as those offered by Quicktron Robotics are designed to be versatile and adaptable to different environments. This flexibility allows them to navigate dynamic and changing conditions in warehouses or distribution centers, providing stability in the face of disruptions. A 2023 study by Interact Analysis suggests that the market for AMRs designed for dynamic environments, such as warehouses with high-density storage or constantly changing layouts, will grow at a CAGR of 22% between 2023 and 2028. This is also evident in the McKinsey survey that found that 93% of respondents intended to make their supply chains far more flexible, agile, and resilient.

AI-powered Inventory Management: A 2023 report by McKinsey & Company suggests that AI-powered demand forecasting and inventory management tools can significantly improve a business's ability to predict and respond to sudden surges in demand for essential goods during flu outbreaks. In a recent Gartner survey, 61% of respondents said technology is a source of competitive advantage, and 20% identified emerging technologies as critical investment areas, with 20% investing in robotics. Gartner’s report suggests that adopting digital supply chain technologies, including intralogistics smart robots that can be deployed in warehouses and distribution centers, will increase in the next three to five years.

Quicktron offers an intelligent AI-powered software platform that optimizes order fulfillment and inventory management. Seamlessly interfacing with customer systems, it facilitates smooth robotic movement, predicts future demand, optimizes storage space, and intelligently groups related goods. This streamlines operation, boosts productivity, and enhances the overall customer experience.

4. Enhancing Efficiency: By automating various aspects of logistics operations, AMRs contribute to increased efficiency and productivity. This is particularly crucial during times of increased demand or when supply chain disruptions threaten to slow down the movement of goods. As per IQ logistics, the spatial savings from reduced warehouse footprints can be up to 85% and reductions in operational costs of up to 65%. Space savings are achieved primarily through storing SKUs higher and denser, and reductions in operational costs result from decreased demand for manual labor. Quicktron’s QuickBin system optimizes space and order fulfillment efficiency by 4X as compared to manual operations, resulting in cost savings, boosting productivity, and reducing reliance on manual labor even in order peaks.

Conclusion:

As the world grapples with health crises like flu outbreaks, the importance of resilient and adaptable logistics and supply chain systems becomes evident. Autonomous Mobile Robots(AMRs) stand at the forefront of technological solutions, offering a way to address workforce shortages, ensure contactless operations, and enhance overall efficiency. By leveraging these innovations, industries can better navigate the challenges posed by health emergencies, contributing to the stability and reliability of global supply chains.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.