Less is More: We relentlessly innovate to maximize ROI for our clients

As competition in the logistics industry intensifies, enterprises must not only improve operational efficiency but also reduce costs to the maximum while ensuring service quality. How can businesses achieve efficient intelligent warehousing with lower investments?

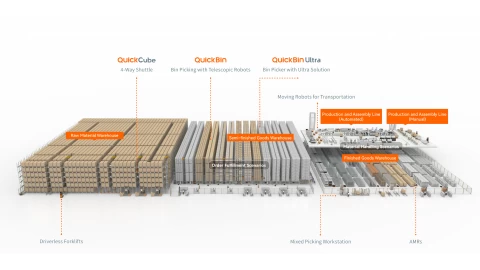

Quicktron simplifies complexity with its new QuickBin solution that leverages collaboration between fewer robots. After successive upgrades to the telescopic robots with vacuum suction, model C56, Quicktron has unveiled the innovative small tote-handling robot, model M5F. This offers enterprises a solution to "achieve efficiency with fewer robots," resulting in shorter ROI cycles and higher returns.

Achieve the Same Efficiency with Fewer Robots

Less is more, the QuickBin solution integrates innovations in robots, workstations, and storage racks, optimizing robot operations and workflows. Businesses can achieve significant efficiency gains without increasing the number of robots. The design advantages include:

-

Reduce M5F Robot Investment by 40%:

The M5F, responsible for horizontal transportation, reaches a maximum speed of 4.5 m/s with a load-bearing acceleration of no less than 2 m/s². Its curved-turn functionality allows for agile operation in confined spaces, reducing operation time compared to traditional linear routes. With the same throughput, robot usage can be reduced by 40%. This enhances warehouse storage capacity and operational efficiency, reducing transportation and time costs. Furthermore, the M5F has undergone rigorous durability testing, ensuring stability and lowering long-term maintenance and replacement costs. -

Reduce C56 Robot Investment by 20%-50%:

Quicktron's innovative M5F features a single-column fork-arm structure supporting dual-layer buffer zones. The super A-category storage is expanded to three times the size of the original QuickBin solution. Consequently, vertical transport handled by the C56 is reduced by 20%-50%, significantly cutting investment costs. -

Higher Space Utilization for Lower Storage Costs:

The upgraded QuickBin supports multi-layer buffering and deep storage. The M5F accommodates picking heights as low as 330mm, while the C56 supports picking heights up to 12m. This maximizes storage density within limited warehouse space, improving warehouse utilization rates. -

Modular Scalability for Reduced Future Costs:

The modular design of QuickBin allows customers to flexibly adjust system scale based on actual needs without overhauling the entire warehousing system. Businesses can scale with growth by adding robots or adjusting picking solutions, avoiding large-scale equipment replacements.

Achieve More with Better Products at Lower Costs

The M5F delivers exceptional performance beyond its speed breakthroughs. Its industry-leading endurance enhances operational efficiency while minimizing charging and downtime dependency. Key design features include:

- 11-Hour Ultra-Long Battery Life

With high speed and 11-hour battery life, the M5F can complete more tasks in less time without requiring mid-shift charging for an 8-hour work cycle. A single charge supports up to 11 hours of operation. Compared to frequent charging and high maintenance requirements of similar robots, the M5F substantially reduces energy and maintenance expenditures.

- Excellent Ergonomic Design

The newly upgraded workstation features a 15° tilt angle for tote entry, enhancing ergonomic compatibility. While maintaining 0-second tote switching at dual operation points, the distance between the tote and the operator is reduced to just 50mm, offering a shorter and more comfortable picking experience. The adjustable pick height design accommodates height differences across various regions worldwide.

- QuickBin+ Hybrid Solution for Expanded Possibilities

The QuickBin+ hybrid solution enables the collaboration of various robot types, handling both "bin-to-person" and "shelf / pallet-to-person" picking tasks. This consolidates medium, large, and small items into a single environment. Intelligent scheduling and path optimization ensure efficient collaboration within the warehouse.

These superior capabilities allow enterprises to access cutting-edge technology and better product performance without bearing high equipment costs. Compared to similar products, the M5F delivers a more efficient and durable solution, helping businesses achieve a higher cost-performance ratio.

Suni develops engaging content, manages impactful social media campaigns, and expertly handles online ads, webinars, podcasts, and video production. She builds strong client relationships by providing support and resources that help drive their sales success. Using a data-driven approach, Suni continually refines strategies and collaborates effectively to stay ahead in the fast-paced digital landscape.