Eight Years Powering Fashion Logistics with Robotics

How Quicktron Uses Robotics to Eliminate Operational Bottlenecks and Empower Brand Growth

Competition in the fashion industry has expanded far beyond products and marketing—extending deep into every layer of the supply chain. Faced with seasonal fluctuations, massive SKU volumes, and sharp order peaks, traditional warehousing and logistics models are increasingly unable to support the speed and scalability that fashion brands demand.

As a long-term innovator in intelligent logistics robotics, Quicktron has spent more than eight years delivering advanced automation solutions tailored to the fashion industry—helping brands break efficiency bottlenecks and accelerate their transition toward smart logistics.

Key Logistics Challenges in the Fashion Industry

- Efficiency Bottlenecks Under Peak Pressure: The traditional “person-to-goods” picking model struggles under surging order volumes, especially during major e-commerce campaigns. Manual picking efficiency is inherently limited—workers may walk tens of kilometers per day yet still fail to keep up with peak demand, directly impacting delivery speed and customer experience.

- High Space Costs and Low Utilization: Large SKU assortments require extensive storage space, while conventional warehouse layouts consume excessive aisle area and deliver low space efficiency. As rental costs continue to rise, warehouses face a persistent dilemma of high cost and low storage density.

- Accuracy and Damage Risks: High-intensity manual operations increase the likelihood of picking errors, mis-shipments, and omissions—damaging brand reputation. Meanwhile, frequent handling of high-value goods raises the risk of damage, resulting in hidden operational losses.

Quicktron’s Intelligent Solutions for Fashion Logistics

1. Quick Pick “Goods-to-Person” System: A Breakthrough in Efficiency

By deploying AMR robots to transport shelves directly to workstations, Quicktron enables a fundamental shift from “people searching for goods” to “goods moving to people.”

Results include:

- In a VIP.com project, achieving 5 items per square meter and 24,000 items picked per day by just 9 operators

- 50–70% reduction in picking labor

- Picking accuracy exceeding 99.99%

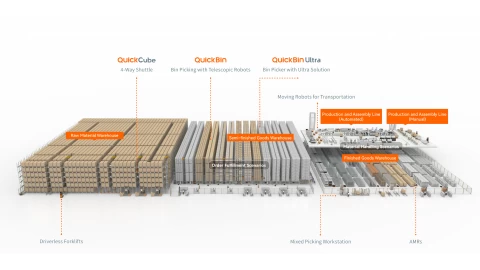

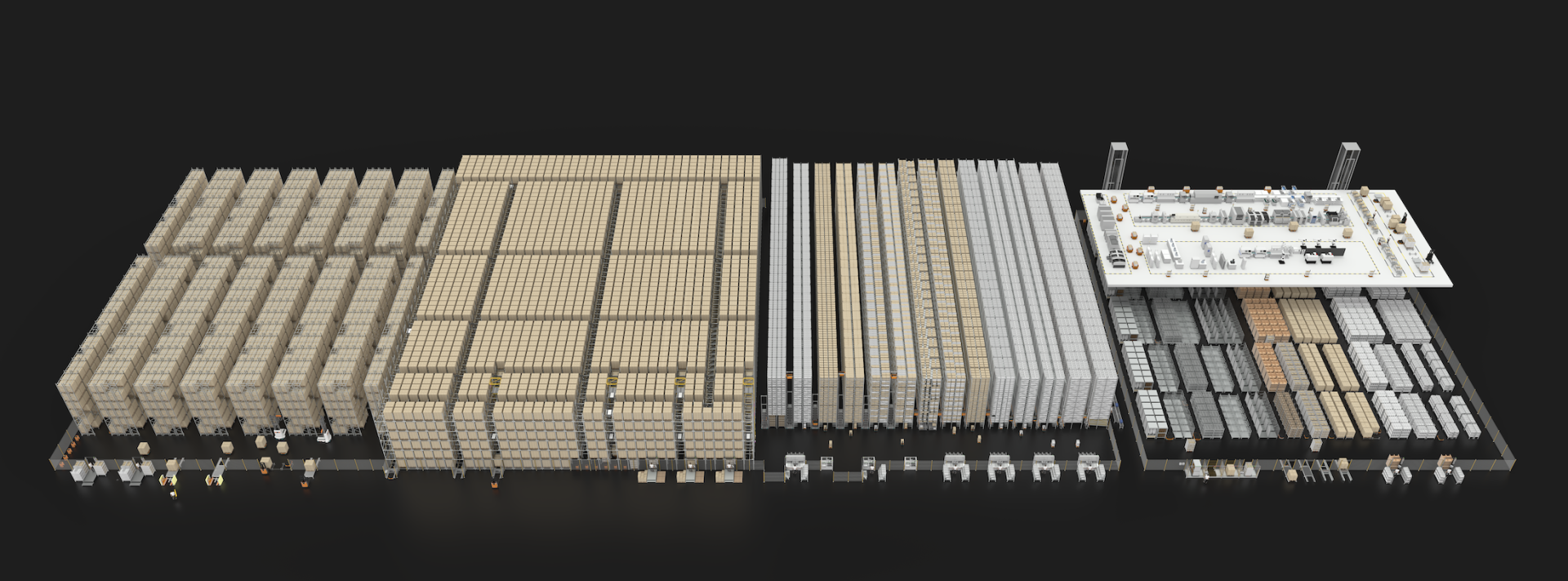

2. High-Density Storage Solutions: Maximizing Space Value

- QuickBin Ultra: Ultra-thin robots (only 300 mm high) combined with narrow-aisle design, increasing storage density by 60%

- QuickCube: Four-way shuttle systems integrated with AMRs, improving space utilization by up to 50%

3. QuickMix Unified Scheduling: Flexible Operations at Scale

QuickMix intelligently coordinates multiple robotic systems, automatically selecting optimal workflows based on order profiles. This enables seamless scalability and adaptability—crucial for the fast-changing demands of the fashion industry.

Proven Success Across Global Fashion Scenarios

1. OKAY Pure Naturals (USA)

The U.S.-based natural skincare brand deployed Quicktron’s goods-to-person automation in a 2,000 m² warehouse with 20 AGV robots.

- Achieved ROI within three years

- Warehouse efficiency increased by 300%

- Order accuracy reached 99.99%

2. Dubai Smart Logistics Center

As the Middle East’s first intelligent robotic fulfillment hub, IQ Fulfillment:

- Supports 24-hour delivery commitments

- Provides end-to-end services including smart storage, picking, and quality inspection

- Demonstrates Quicktron’s global delivery and service capabilities

3. VIP.com Mega Promotion Support

During the 9.9 Beauty Festival, Quicktron’s systems enabled VIP.com to:

- Multiply picking efficiency

- Significantly reduce error rates

- Successfully handle extreme order surges

4. Xinyi Beauty Industry Park (China)

Serving brands such as Inoherb and Pechoin:

- Productivity increased from 200–300 items per day to 5,000–6,000 items per hour

- 20 robots deployed in a 4,000 m² warehouse

- Near-lights-out automated operations achieved

Continuous Evolution Driven by Technology

Quicktron’s solutions go beyond hardware automation—software intelligence continuously optimizes performance:

- Data analytics to identify order patterns

- Machine learning to refine scheduling strategies

- Real-time adjustments to respond to demand volatility

During major shopping events such as Singles’ Day, the system dynamically balances uncertainty while maximizing throughput without compromising accuracy.

Industry Value and the Road Ahead

For fashion brands, Quicktron delivers more than operational efficiency—it provides strategic, long-term advantages:

- Agile Market Response: Flexible systems adapt quickly to new product launches, promotions, and seasonal changes—shortening time-to-market.

- Optimized Cost Structure: Improved labor efficiency and space utilization reduce errors and operational losses, enabling sustainable cost optimization.

- Enhanced Customer Experience: Fast, accurate order fulfillment directly improves consumer satisfaction and strengthens brand loyalty.

- Global Service Network: From China to the Middle East, Europe, and North America, Quicktron has established a global project delivery and service footprint—supporting fashion brands’ international expansion.

Automation as a Foundation for Sustainable Growth

For the fashion industry, carbon neutrality and sustainability goals often translate into two actionable priorities: reducing supply chain emissions and improving operational efficiency. Within warehousing and fulfillment, lowering carbon intensity per order and improving reverse logistics efficiency represent tangible, scalable opportunities.

Quicktron’s in-warehouse automation solutions provide a solid operational foundation for fashion enterprises on their path toward 2030 sustainability goals—delivering stable fulfillment, optimized resource usage, and measurable performance improvements.

Overseas Digital Marketing Specialist at Quicktron, specializing in global brand communication, digital marketing and content creation for intelligent robotics and logistics automation.