Quicktron Industrial Park Awarded “Outstanding” Net Zero Carbon Certification

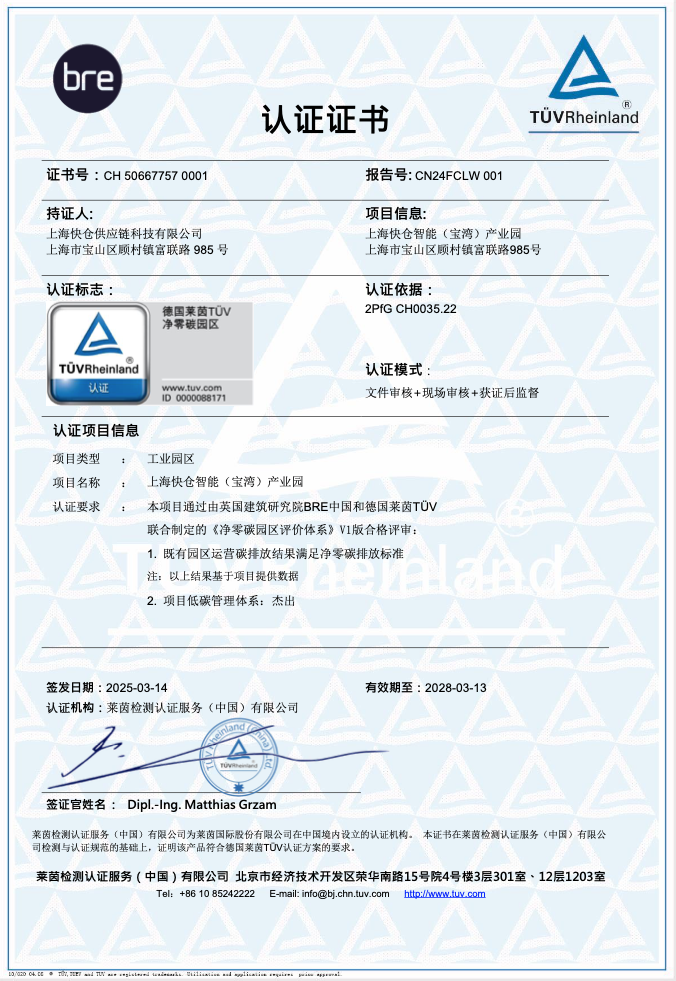

On March 14, the Quicktron Smart Industrial Park in Shanghai was awarded the “Outstanding” Net Zero Carbon Park Certification by a leading international authority, recognizing its excellence in low-carbon and intelligent operations. This milestone marks a significant step forward in Quicktron’s commitment to sustainable development and sets a new industry benchmark for zero-carbon industrial parks.

A Model for Green Operations Located in Baoshan District, Shanghai, the Quicktron Smart Industrial Park spans 67 acres with a building area of nearly 92,000 square meters. It integrates R&D, manufacturing, and ESG practices. By incorporating solar, wind, and energy storage systems with intelligent energy management, the park achieves an annual reduction of 830 tons of CO₂ emissions and saves 311 tons of standard coal.

The Net Zero Carbon Park Certification, officially filed with the Certification and Accreditation Administration of China (CNCA), is one of the most advanced and authoritative low-carbon standards in the domestic construction sector. This achievement reflects Quicktron’s dual leadership in intelligent manufacturing and green innovation.

ESG Philosophy: Technology for Good, Responsibility in Harmony

Since 2021, Quicktron has continuously invested in researching industrial scenarios related to emerging industries and actively responded to the national "dual carbon" goals. ESG has been viewed as the core driver of the company’s long-term value growth.

Environment (E): Empowering Green Logistics with Technology Quicktron promotes green transformation through technological innovation. From intelligent robots to park operations, the company is committed to achieving low-carbon outcomes. At the Quicktron Smart Industrial Park in Shanghai, the integration of renewable energy and carbon offset measures has enabled net-zero carbon operations. Additionally, Quicktron’s robotic solutions help customers reduce energy consumption and carbon footprints, contributing to the development of green supply chains.

Social (S): Innovation Giving Back to Society Quicktron enhances industry efficiency through technology, addressing labor shortages, ensuring employee safety, and creating a diverse and inclusive work environment. The company also actively participates in social welfare initiatives, such as collaborating with universities to train robotics talent, promoting educational equality, and expanding access to technology.

Governance (G): Driving Sustainable Development with Transparency Quicktron has established a sound compliance management and risk control system, implementing good governance measures such as data security protection and board diversity. The company regularly discloses ESG progress and maintains transparent communication with stakeholders.

Empowering Customers to Achieve ESG Goals In addition to practicing ESG principles within its own operations, Quicktron empowers customers to achieve their sustainability goals through technological innovation. The company has helped build 24/7, unmanned, automated "dark factories" for numerous clients.

A Manufacturing Plant in Tianjin By integrating Quicktron’s automated production lines and intelligent management systems, the plant achieved its goal of “smart manufacturing and a zero-carbon factory.” The production process has become highly automated and digitalized, significantly enhancing production efficiency and product quality. Furthermore, advanced smart technologies, such as cloud platforms, 5G, big data, and AI, combined with green manufacturing techniques, have been utilized to create a zero-carbon smart workshop, smart logistics, and a smart industrial park.

Maersk 3PL Warehouse

The warehouse has adopted Quicktron’s QuickBin solution, enhancing picking efficiency while addressing the pain point of garment style sorting and packing. By using M5 bin movers to execute sorting and allocation plans, the solution effectively solves the need for sorting the same style into the same box and organizing SKUs within each box, specifically for B2B operations in the apparel industry.

Changan Minsheng – Lighthouse-Level Low-Carbon Practice with Visualized Systems

The "RDC Totes Intelligent Robot Warehouse" developed by Quicktron in collaboration with Changan Minsheng Logistics has become a successful lighthouse-level low-carbon practice in the automotive parts logistics industry. This project saves several million yuan annually. Since its implementation, the project has achieved a 195% improvement in storage accuracy and a 99.99% picking accuracy. Additionally, it successfully met the customer’s needs to balance epidemic prevention with stable, high production output. This powerful demonstration proves the significant value of the "dark warehouse + unmanned transport" new model in the automotive parts logistics sector.

Suni develops engaging content, manages impactful social media campaigns, and expertly handles online ads, webinars, podcasts, and video production. She builds strong client relationships by providing support and resources that help drive their sales success. Using a data-driven approach, Suni continually refines strategies and collaborates effectively to stay ahead in the fast-paced digital landscape.