Quicktron: Powering Global Smart Warehousing with Full-Scenario Hybrid Solutions

By delivering full-scenario hybrid automation solutions, Quicktron is empowering intelligent warehouse upgrades across industries worldwide.

Against the backdrop of accelerating digitalization and automation in global supply chains, warehouse logistics is becoming increasingly complex. Enterprises are no longer satisfied with automation in isolated scenarios; instead, they require seamless coordination across multiple scenarios within a unified system, forming a closed-loop, end-to-end automated workflow.

As a global leading provider of intelligent logistics robot solutions, Quicktron Intelligent Technology Co., Ltd. (hereinafter referred to as “Quicktron”) leverages its QuickMix full-scenario hybrid solution to integrate multiple robot types under a unified RCS (Robot Control System). This enables highly flexible, high-density, and intelligent automation upgrades for industries including e-commerce, 3PL, pharmaceuticals, apparel, cosmetics, and manufacturing.

With business operations spanning more than 20 countries and regions, Quicktron’s benchmark projects worldwide fully demonstrate its strength in delivering “full-scenario, full-process, and fully intelligent” solutions.

QuickMix: Redefining the New Paradigm of Warehouse Automation

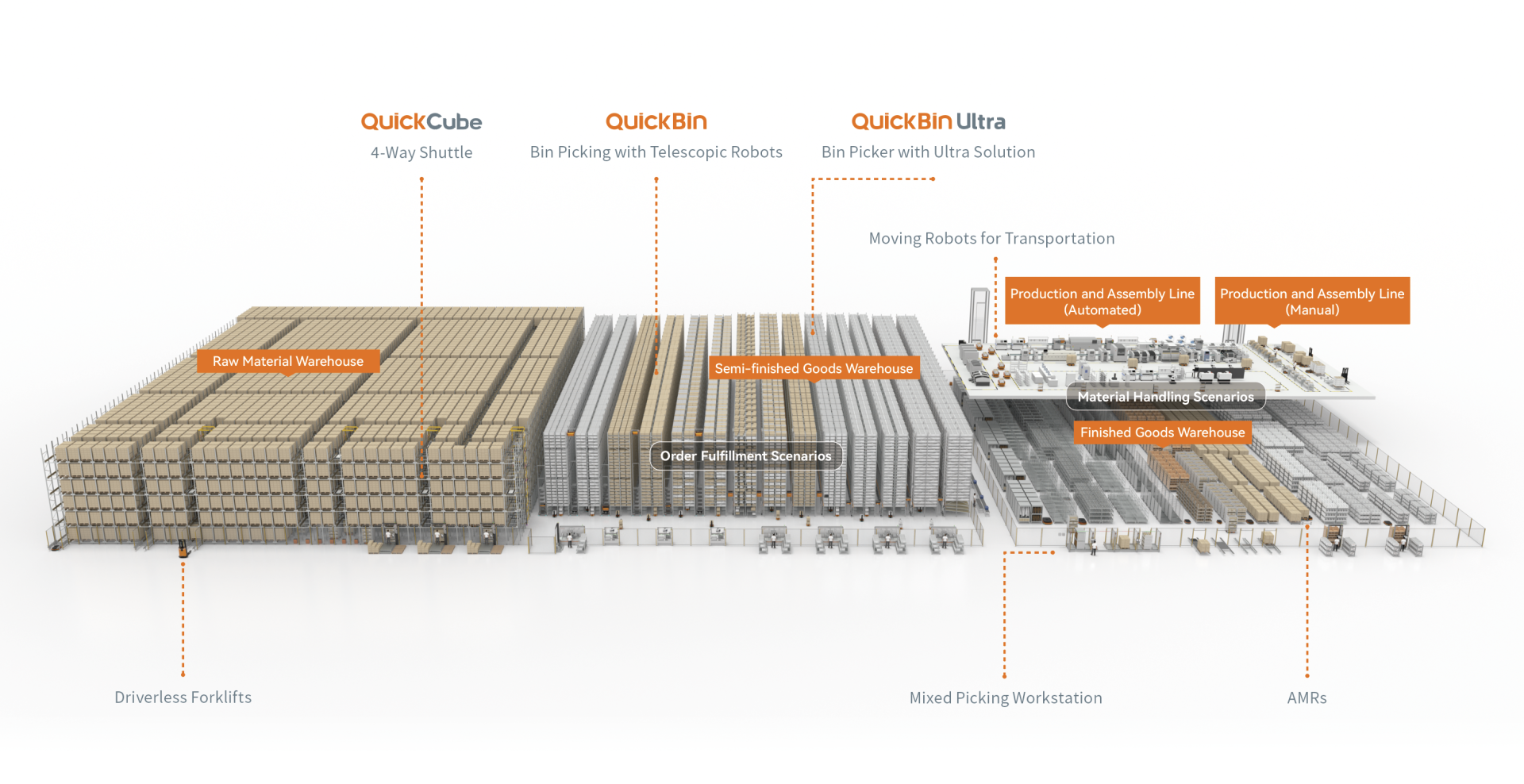

The QuickMix full-scenario hybrid solution integrates multiple automation scenarios—such as bin-to-person, shelf-to-person, pallet-to-person, dense storage, and flexible material handling—into a single intelligent scheduling system. Supporting collaboration among different robot models, QuickMix flexibly addresses complex and dynamic operational requirements.

Key advantages include:

- Multi-scenario integration: A single warehouse can simultaneously support piece picking, case handling, and pallet inbound/outbound operations.

- System unification: A single RCS manages multiple device types and seamlessly connects with upstream business systems to enable end-to-end automation.

- High scalability: Modular solution design supports future business growth and system expansion.

- Optimized cost efficiency: Achieves the optimal balance between storage density and operational cost within limited space.

With QuickMix, warehouses are no longer fragmented collections of single-function modules, but unified, intelligent systems capable of handling complexity at scale.

QuickCube & QuickBin Ultra: End-to-End Hybrid Automation in Action

Within QuickCube, Quicktron’s pallet-level full-process automation solution, an innovative slim vertical lift installed directly on racking rails replaces traditional lifts and works in coordination with Quicktron’s proprietary four-way shuttle to achieve high-density pallet storage.

By removing lower-level racks, the system can integrate a G2P shelf-to-person solution. During outbound operations, AMRs transport pallets to buffer zones, where Quicktron’s omnidirectional autonomous forklifts convey pallets to loading docks—completing a fully automated pallet workflow.

The QuickCube pallet-based upper-storage, lower-picking system supports both full-pallet and split-pallet outbound operations and can also replenish the QuickBin Ultra high-density bin storage system.

As a high-throughput bin storage and retrieval solution, QuickBin Ultra features

- A5 large bin-handling robots with linear speeds up to 3 m/s and 200 picks/hour

- M5F/M5E small bin transport robots with fork speeds up to 4.5 m/s

- Up to 600 bins/hour per workstation

This large–small robot collaboration maximizes throughput and operational efficiency.

Furthermore, QuickBin Ultra can be flexibly combined with legacy QuickBin systems to support hybrid G2P picking under existing racks or connect directly to conveyor lines for bin outbound operations. Standardized modules with multiple configuration options significantly enhance deployment flexibility.

All hardware systems across these solutions are centrally managed and scheduled by Quicktron’s RCS, reducing operational complexity for users and integrators while greatly improving scalability across scenarios.

Global, Multi-Industry Benchmark Projects

Mercado Libre (Brazil): Latin America’s Largest Goods-to-Person Warehouse

Mercado Libre Brazil Warehouse Upgrade – Project Overview

| Item | Details |

| Automated Area | 15,000 m² |

| Number of Robots | 350 units |

| Number of Racks | 6,400 units |

| Throughput | 105,000 orders per day |

Hundreds of robots operate seamlessly across the facility, ensuring fast order fulfillment and supporting Mercado Libre’s continued growth in the Latin American market.

Radial (Netherlands): World’s First Hybrid-Storage G2P Project

Radial, a global leader in e-commerce fulfillment services, required a system capable of handling bins, pallets, and shelving within one unified platform at its Groningen site. Through QuickMix, Quicktron delivered the world’s first hybrid-storage goods-to-person system.

Radial Netherlands (Groningen) Project Overview

| Item | Details |

| Automated Area | 8,500 m² |

| Number of Robots | 300 units |

| Processing Throughput | 40,000 order lines per day |

| Labor Cost Reduction | 40% |

By integrating QuickBin with pallet solutions and enabling centralized workstations to process multiple order types simultaneously, the system significantly enhanced flexibility and redefined warehouse fulfillment efficiency.

TCL Wankezi: Flexible Design for Irregular Pallet AS/RS

In a manufacturing scenario, Guangdong Wankezi Intelligent Control Technology, a core supplier for TCL air conditioners, faced constraints from an irregular building layout and a clear height of only 4.9 meters. Quicktron delivered a customized three-level automated storage solution, balancing throughput requirements with future scalability.

Wankezi Intelligent Control Technology Warehouse – Project Overview

| Item | Details |

| Automated Area | 3,100 m² |

| Four-Way Shuttle Robots | 10 units |

| AMRs (Autonomous Mobile Robots) | 12 units |

| Storage Capacity | 2,690 pallet positions |

| Inbound & Outbound Accuracy | 100% |

Through flexible layout planning and simulation-based validation, the project achieved precise throughput matching while reserving room for future expansion—setting a benchmark for manufacturing warehousing upgrades.

Blue Ocean Logistics: Intelligent Handling for Publishing & Printing

At the Modern Publishing Logistics Center of Chinese Media Group in Nanchang, Quicktron designed a multi-robot collaborative handling solution for Blue Ocean Logistics, marking the first large-scale deployment of forklift robots working in relay with AMRs in the publishing industry.

Blue Ocean Logistics – Modern Publishing Logistics Center (Chinese Media Group) Project Overview

| Item | Details |

| Automated Area | 26,000 m² |

| Number of Robots | 61 units (including 9 autonomous forklifts) |

| Picking Efficiency Improvement | +200% |

| Picking Accuracy | 99.99% |

This innovative relay-based handling model demonstrates Quicktron’s leadership in multi-robot collaboration and provides a new blueprint for logistics transformation in the publishing sector.

From Local Optimization to Full-Scenario Empowerment: Shaping the Future of Smart Logistics

From logistics to manufacturing, Quicktron’s extensive global portfolio validates the value of QuickMix full-scenario hybrid intralogistics solutions. These solutions not only address diverse industry needs but also help customers gain competitive advantages through intelligence, flexibility, and high-density storage.

Quicktron believes that the future of warehousing lies not in isolated automation breakthroughs, but in system-level collaboration and full-scenario integration. Backed by global project experience and continuous product innovation, Quicktron is leading smart warehousing into its next phase of evolution.

Overseas Digital Marketing Specialist at Quicktron, specializing in global brand communication, digital marketing and content creation for intelligent robotics and logistics automation.