Quicktron Unveils the new "All-in-one" Hybrid Goods-to-Person Picking System

Quicktron Unveils its unique Prototype for Goods-to-Person Solution's category which is the merger of merger of Quicktro...

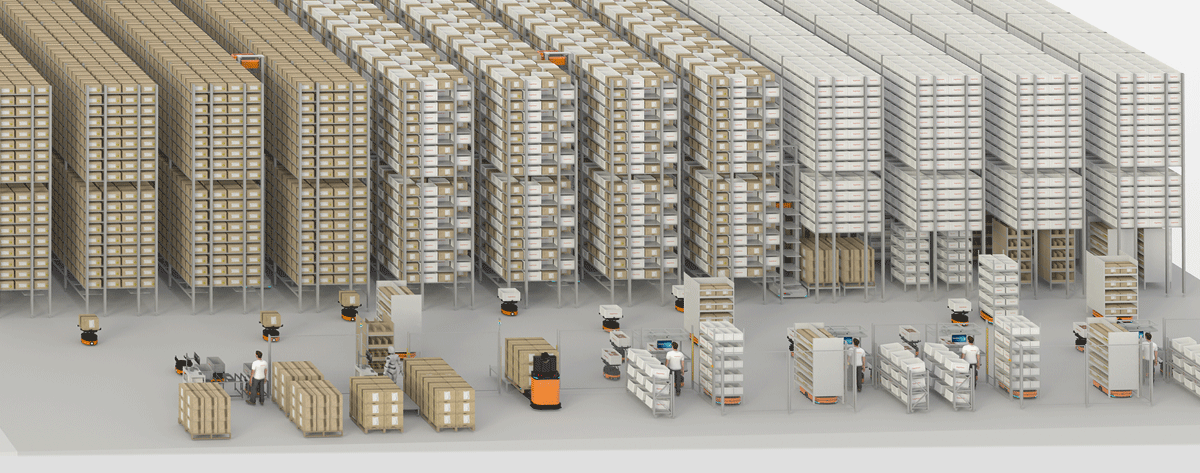

Quicktron Robotics introduced the groundbreaking modularized prototype for the Goods-to-person solutions category, solidifying its position as a leader in providing top-tier intralogistics solutions. In today's world, meeting the rising customer demands with a single solution has become increasingly challenging. But thanks to Quicktron these fulfillment challenges can now be met more efficiently. This compound solution will enhance efficiency while reducing costs. Quicktron Robotics is continuously accelerating intralogistics with advanced technology.

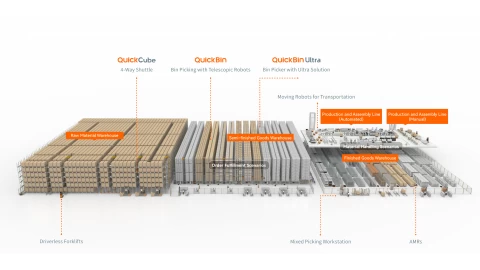

- Merging QuickBin (QB) and Shelf/Rack-to-person technologies into a single GTP solution that works simultaneously in one operational area.

- Picking of all-size goods i.e., small, medium, and large, can be handled through the centralized workstations.

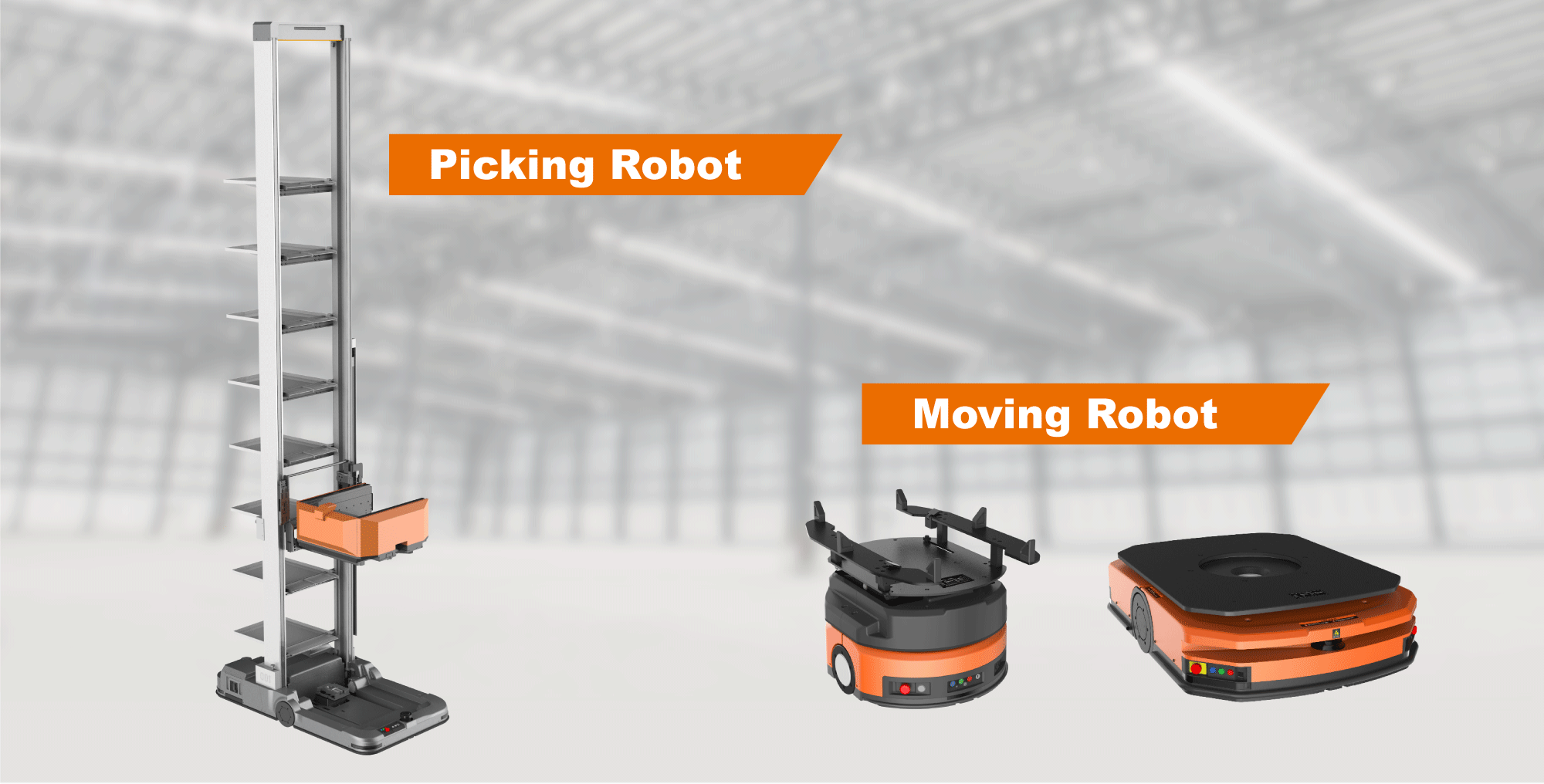

This prototype is an all-in-one GTP solution that works with the collaboration of picking and two types of moving robots. Picking robots to perform storage and retrieval and move within the aisles in the storage area while moving robots transfer bins/racks to or from workstations. This unique prototype offers plenty of options to store, move and pick goods. You can choose one-stop storage with centralized picking and increase the delivery speed with higher throughput and scalability.

How does this modularized G2P solution work?

- Goods can be stored separately in a centralized storage area, retaining their distinct QB or shelf/rack storage classification, and then delivered to the centralized workstations.

- Alternatively, you may also combine the storage by using different combinations of the QB storage and the shelf/racks, then deliver to centralized workstations for quick delivery.

Adaptable to Multiple Application scenarios

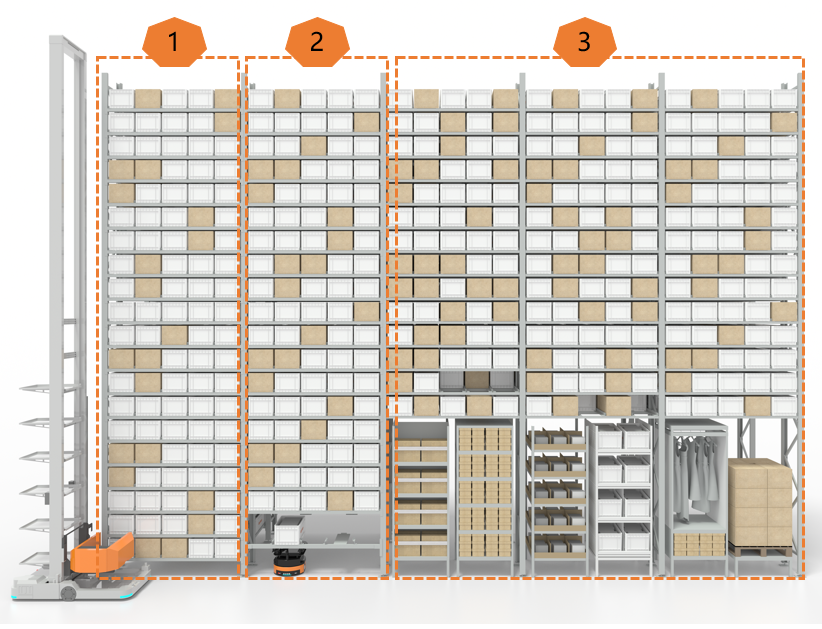

1: For scenarios with lower traffic and significant storage requirements such as the back end of a large warehouse, QB higher storage is preferred.

2: For scenarios with high traffic requirements, keep the bottommost portion of storage space vacant for the temporary storage of goods which enhances the traffic flow.

3: For the unsuited oversized bins, the shelf mode in the lower portion can be adopted which increases the size range of SKUs Storage (clothing hanging).

3: For sorting scenarios, sort the goods by picking from the upper portion and then placing them on a shelf/rack in advance, this is how multiple SKUs that need to be sorted are organized on the shelf and moved at once, efficiently solving the sorting problem (Same type items of the store).

Benefits of the latest technology to your warehouse operations

- With the coordination of 3 different types of robots moving around one centralized workstation, the one-stop solution increases the number of choices for more efficient warehouse automation.

- The ability to accommodate goods of various sizes greatly improves traffic flow.

- It increases speed and throughput while ensuring optimum efficiency with 99.99% picking accuracy. This solution will help in reducing costs, save energy, and boost productivity.

- Businesses can streamline their operations and adapt quickly and effectively to market demand shifts by integrating warehouse automation solutions. Extremely adaptable in order peaks and meeting fulfillment challenges

- The system enables handling goods of various sizes by one solution at a single workstation, utilizing warehouse space to its full potential and eliminating the need for multi-zone operations.

- With a lot of flexibility in Quicktron’s robotic solutions, each industry can automate its logistics operations efficiently. For more details click here.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.