GTP Solutions For Micro-Fulfillment Centers (MFCs): Effective Delivery, Better Results

In this article, we will explore Quicktron Robotics and its contribution to the world of MFCs....

Micro-fulfillment centers (MFCs) are quickly becoming the new trend in the world of e-commerce, especially for retailers to streamline their supply chain operations and reduce shipping costs. According to precedence research, “the global micro fulfillment market size was accounted at USD 3.53 billion in 2022 and is projected to hit around USD 113.84 billion by 2032, growing at a CAGR of 41.53% during the forecast period 2023 to 2032." The MFCs are small, automated warehouses designed to optimize order fulfillment, offering faster and more efficient delivery options to customers. Quicktron Robotics is a leading robotics company that specializes in developing and deploying automation solutions for warehouses and fulfillment centers. In this article, we will explore Quicktron Robotics and its contribution to the world of MFCs.

The Benefits of MFCs for Retailers and Consumers

MFCs are essentially smaller versions of traditional fulfillment centers, designed to operate in more urban areas. They offer numerous benefits to both retailers and consumers. For retailers, MFCs can help reduce the costs associated with shipping, inventory management, and order fulfillment. By bringing the warehouse closer to the customer, retailers can improve delivery times, reduce shipping costs, and offer more efficient delivery options such as same-day and next-day delivery. Additionally, MFCs can help retailers optimize their inventory management, allowing them to reduce storage costs and minimize the risk of stockouts.

For consumers, MFCs offer faster and more convenient delivery options. By leveraging the latest automation technologies, MFCs can fulfill orders in a matter of hours, providing customers with a more personalized and efficient delivery experience. This can help increase customer satisfaction and loyalty, leading to increased sales and revenue for retailers.

New research from Interact Analysis shows that 7,300 automated micro-fulfillment centers (MFCs) will be installed by the end of 2030, up from just 86 at the end of 2021. With the growth in the short run is mainly driven by demand for same-day grocery delivery.

Quicktron Robotics: Leading the Way in MFC Automation

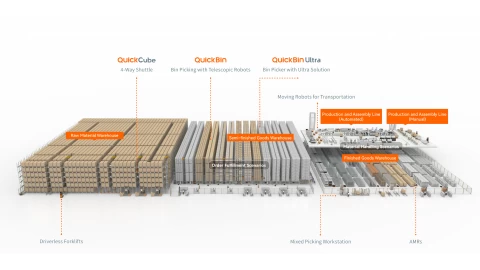

Quicktron Robotics with its range of goods-to-person solutions is leading MFC robotics, its automation technologies include the Quickbin and other smart picking systems. Quickbin is a modular, scalable solution that uses autonomous mobile robots to transport bins of products to pick stations. The system is designed to improve picking efficiency and accuracy, reducing labor costs and errors.

Quicktron Robotics has been making significant strides in the world of MFCs. Innovative robotic solutions such as the QuickBin system are helping retailers to improve their supply chain efficiency, reduce shipping costs, and deliver products to consumers faster than ever before. Quicktron Robotics has established itself as a major player in the industry, with partnerships such as Alibaba Group, KION Group, Cubyn, Winit, and other major companies.

Quickbin: A Game-Changing Solution for MFCs

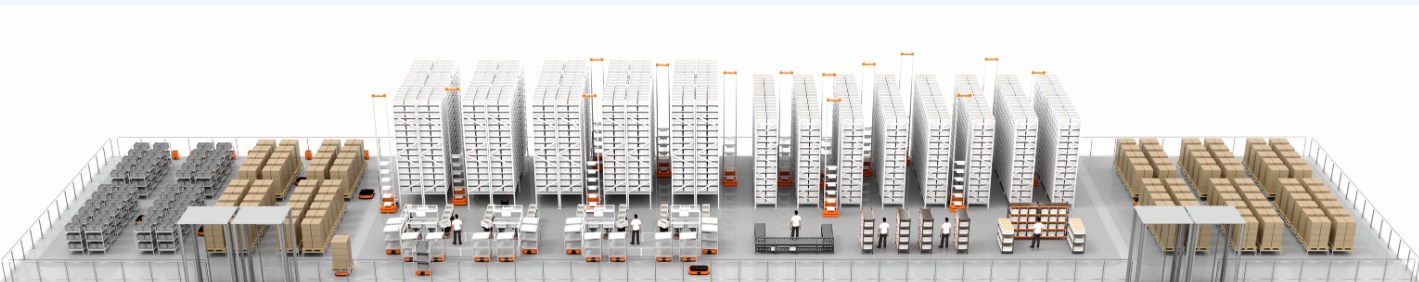

QuickBin is a patented goods-to-person system that uses autonomous mobile robots to transport bins of products to pick stations. The system is designed to work seamlessly with MFCs, allowing retailers to improve their picking efficiency up to 3-4X with 99.99% accuracy. The robots can move at a fast speed and reach up to 8.3 m in height, which is significantly more efficient than a human worker. This means that products can be moved around the MFC much more quickly, and stored higher improving overall efficiency.

The QuickBin system is equipped with advanced sensors and mapping technology, to maximize traffic efficiency and ensure seamless high-speed operations, the shortest optimal path is planned for each robot, allowing the robots to navigate around the MFC autonomously. This eliminates the need for human workers to transport products, reducing the risk of injury and increasing safety in the workplace.

Improve the Supply Chain Efficiency with QuickBin

One of the key advantages of the QuickBin system is its flexibility. The system can be customized to fit a variety of MFC layouts and configurations, making it an ideal solution for retailers of all sizes. The modular design also allows for easy expansion, ensuring that the system can grow with the retailer's needs.

Another advantage of the Quickbin system is its speed. Autonomous mobile robots can move quickly and efficiently around the MFC, reducing pick times and improving overall efficiency. The system can also be integrated with other warehouse management systems, further enhancing its functionality.

The Versatility of QuickBin System

QuickBin system is a versatile and speedy solution for MFCs. It incorporates two types of AMRs, moving robots that can move goods quickly, while tall picking robots can store higher in MFCs saving storage space, and making it possible to pick and deliver goods to the pick stations in a matter of minutes. The system can be integrated with a range of warehouse management systems, AS/RS, WCS, and WMS which keeps inventory management smooth.

In conclusion, micro-fulfillment centers are the future of e-commerce, and Quicktron Robotics is at the forefront of this revolution. With our innovative robotic solutions, we are helping retailers to improve their supply chain efficiency, reduce shipping costs, and deliver products to consumers faster than ever before. As the demand for MFCs continues to grow, Quicktron Robotics looks set to play a key role in shaping the future of e-commerce.

To learn more click here.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.