QuickBin™

Priority Robotics

Thanks for submitting the form!

We will contact you soon.

75% More Storage, 4X Faster Order Fulfillment

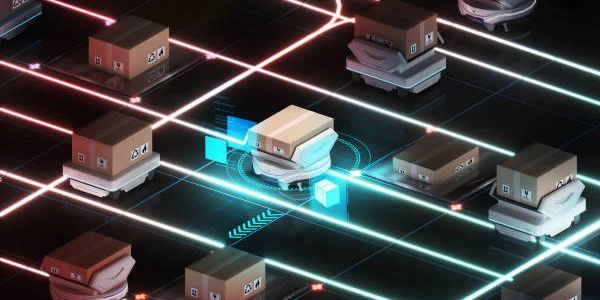

QuickBin™ is our patented bin-to-person picking solution that revolutionizes warehouse operations by leveraging automation through robotics and intelligent software. It enhances efficiency, reduces labor costs, and accelerates deliveries in distribution centers, fulfillment warehouses, and e-commerce hubs.

QuickBin™ solution utilizes robots to automate tasks such as aisle navigation, storage optimization, and transfer of goods to workstations/operators. It eliminates the need for workers to navigate aisles allowing them to focus on more important tasks. With advanced tracking and identification technologies, real-time inventory updates, and seamless integration with warehouse management systems, QuickBin™ provides enhanced visibility and control.

QuickBin™ utilizes two types of robots for optimized storage and smooth transfer of goods between the storage area and workstations. Picking Robots (C56) can reach up to 32.8ft(10m) and navigate the aisles dynamically storing, retrieving, and picking goods within the storage area, while Mini Moving robots (M5) ensure the smooth transfer of goods to and from the picking workstations.

Flexible Two Robotic Operations

Storage Optimization

Adaptable to varying throughput needs

Maximize Storage Efficiency

By utilizing Picking Robots (C56), QuickBin™ leverages the key benefits of ASRS, enabling dense storage and optimized inventory management. The intelligent double mast design of C56 ensures efficient use of vertical space, while its impressive height of 32.8 ft (10m) combined with double deep design unlocks unprecedented control over stock levels, all while achieving a remarkable 99.99% accuracy.

High Density Storage: Double-deep + 32.8ft height

Picking Arm Modules: Telescopic or Vacuum Suction

Seamless Goods-to-Person Handling

In QuickBin settings, these autonomous bots seamlessly transport goods between storage areas and workstations, saving valuable time and eliminating the need for workers to navigate the warehouse. Robots follow one another in 1-2 second intervals and make a queue in front of workstations, resulting in a dramatic reduction in travel time, minimizing inefficiencies and bottlenecks.

Speed 2m/s

Compact design

.png)

Software Platform

Quicktron’s intelligent software platform encompasses WES and RCS which work in tandem to streamline warehouse operations. The combined power of these systems with different combinations enables businesses to meet the evolving demands of modern warehousing with efficiency and agility. Our AI algorithms ensure seamless robotic movement by optimal path planning and make a collision-free environment to maximize traffic efficiency. By analyzing order history, the system optimizes shelf and bin placement for future demand, refines order parameters, and groups related goods in outgoing orders, resulting in elevated shelf hit rates and improved overall warehouse performance.

Patented Technology

QuickBin™, our patented goods-to-person picking technology is an innovation that revolutionizes operations with a strong focus on safety and productivity. Trust in QuickBin for not only heightened productivity but also the added assurance of patented protection.

Australian Application NO.: 2021240488

Australian Application NO.: 2021240487

The Benefits of QuickBin

Flexible, scalable system

Easy expansion: Grow the number of robots as your business grow

Can be customized and configured to fit specific business requirements

-webp.webp)

Unparalleled Efficiency

Pick More, Pick Faster

200,000+ order lines/ day

Efficiency Boost 3-4X

Space Optimization

Stack totes up to 10 meters high with zero gaps, saving valuable floor space

Maximizes storage space, Stores higher stores faster and more.

Quick ROI

Sophisticated investment

Shorter payback period of 1-2 years

Customer satisfaction and profitability

Mitigate the labor shortage

Labor Cost Saved by 50-60% on average

Inventory Accuracy

Accuracy rate 99.99%

Eliminates the risk of stockouts or overstocks